TPM 3D Asia Advanced Materials Printing Center

TPM 3D Asia advanced materials printing center located in Jiangsu Province, cover the area with more than 1000 m2. The center consists of intelligent manufacturing 3D printing display platform, industrial and advanced materials intelligent printing center, medical sterile R&D experiment labs, and SLS post processing center and multimedia conference zone.

3D Printing Digital Medical Center

The center construction includes three phases, we can provide orthopedic insoles, orthopedic pillows, scoliosis braces, knee orthoses, application of surgical guides for head, pelvis, spine and knee joints and 3D printing of braces, as well as orthopaedic standardized implant products development.

Our research

TPM3D has successfully developed 10+ laser sintering additive manufacturing systems, and more than 10 kinds of polymer powder printing material for high-quality parts manufacturing, has more than 30 national patents as well.

Related Products

More items about selective laser sintering

Selective Laser Sintering

TPM3D technical team has been engaged in industrial 3D printing business since 1999 and has become the industry brand with 20 years focusing on 3D printing service。

TPM3D has various customers at home and abroad from the fields of automobile, electrical appliances, electronics, medicals, cultural & creative, education, aerospace, such as Guangzhou Automobile, Dongfeng Motor, Gree Group, LG Electronics, TTI, Fohan Service Bureau, Tongji University, Southern University of Science and Technology, University of Texas at Austin, and Massey University Auckland.

Selective Laser Sintering Printing Materials

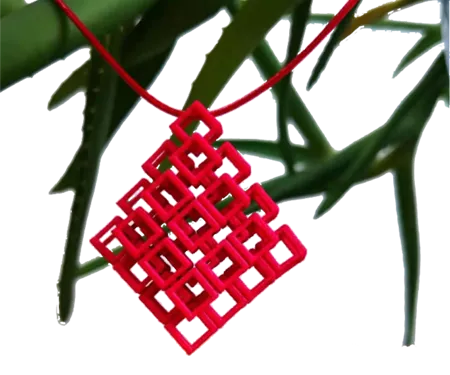

The most common material for selective laser sintering is nylon, a powerful engineering thermoplastic that can be used for functional prototyping and end-use production. Nylon is ideal for complex assemblies and durable parts with high environmental stability.

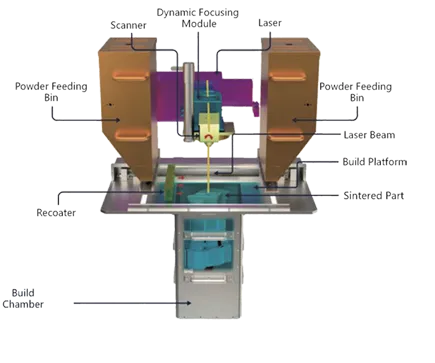

Selective Laser Sintering Mechanism

Selective laser sintering occurs primarily in the liquid state, where powder particles form a micro-melted layer on the surface, resulting in a reduction in viscosity and the formation of concave radial bridges between the particles, known as necking, the material's response to lowering its surface energy.

Selective Laser Sintering Technology

Selective laser sintering is an additive manufacturing layer technology that involves the use of a high-power laser to fuse small particles of plastic, metal, ceramic or glass powder into a substance with a desired three dimensional shape.

Selective laser sintering | The most promising 3D printing technology

With the development of 3D printing technology and printing materials, Selective laser sintering (SLS) printing technology has become one of the most promising 3D printing technologies with its unique advantages.

Although FDM currently has the most users, mainly because it is a desktop-level 3D printing device and the price is relatively low. However, the precision of its printed products is low, which cannot fail to meet the needs of other industrial production. The printing accuracy of SLS is very good, and it can print a variety of materials. At present, it is widely used in industrial manufacturing verification. However, with the continuous enrichment of printing materials, the cost gradually decreases. In addition to the application in development and verification, terminal The application of the product is also more and more extensive. For example, household consumer electronics, personalized rehabilitation aids, and even some auto parts can be used directly after 3D printing, which will occupy a very large market share in the future.

User Reviews

What users say about TPM 3D printing

Frequently Asked Question

Do you have any question?

Selective Laser Sintering (SLS) technology is an additive manufacturing technique that employs a high-powered laser beam to fuse powdered materials like plastics, metals or ceramics layer by layer. It enables creation of intricate three dimensional objects directly from digital designs without the need for molds or tooling.

Selecting the appropriate supplier is critical in securing reliable and high-quality equipment as well as receiving comprehensive support and expertise. A reliable SLS supplier should offer cutting-edge printing technology with precise features and capabilities for consistent and precise results, plus technical assistance, training, and ongoing support to maximize investment and optimize performance.

SLS printing can have wide-reaching applications across various industries, particularly those related to automotive, aerospace, healthcare, consumer goods, engineering, and consumer product production. SLS allows rapid prototyping of complex parts as well as customization and low volume production with cost-effective solutions and reduced lead times compared with traditional manufacturing methods.

When choosing an SLS printer supplier, take into account factors such as their reputation, experience and customer reviews as well as quality and reliability of equipment (print resolution, build volume and material compatibility) used. Assess their level of technical support as well as any training programs or aftersales services they may provide to ensure seamless integration and ongoing assistance from them.

Yes, a reliable SLS printer supplier can assist in selecting materials suitable to your applications and goals. They will offer advice regarding material properties, compatibility, and performance before helping select suitable options that meet desired results such as strength, flexibility, durability or heat resistance.

Many suppliers of SLS printers provide demos or trial periods so customers can assess the equipment's capabilities and performance before making a buying decision. This helps determine its suitability for specific needs as well as provide invaluable hands-on experience before committing.

A reliable SLS printer supplier should offer support services like technical assistance, software updates and troubleshooting guidance as well as training programs designed to equip you and your team with all of the skills and knowledge necessary for using and optimizing SLS equipment effectively and achieving desired results.

A highly skilled SLS printer supplier can be an invaluable partner in the success of your business, offering cutting-edge technology, expertise, and support that enhance your 3D printing capabilities - leading to improved product development, accelerated prototyping, reduced manufacturing costs and increased innovation - ultimately helping keep your competitive edge alive while driving growth for you and your organization.