TPM 3D Asia Advanced Materials Printing Center

TPM 3D Asia advanced materials printing center located in Jiangsu Province, cover the area with more than 1000 m2. The center consists of intelligent manufacturing 3D printing display platform, industrial and advanced materials intelligent printing center, medical sterile R&D experiment labs, and SLS post processing center and multimedia conference zone.

3D Printing Digital Medical Center

The center construction includes three phases, we can provide orthopedic insoles, orthopedic pillows, scoliosis braces, knee orthoses, application of surgical guides for head, pelvis, spine and knee joints and 3D printing of braces, as well as orthopaedic standardized implant products development.

Our research

TPM3D has successfully developed 10+ laser sintering additive manufacturing systems, and more than 10 kinds of polymer powder printing material for high-quality parts manufacturing, has more than 30 national patents as well.

Related Products

More items about polymer powder

Polymer Powder

TPM3D technical team has been engaged in industrial 3D printing business since 1999 and has become the industry brand with 20 years focusing on 3D printing service。

TPM3D has various customers at home and abroad from the fields of automobile, electrical appliances, electronics, medicals, cultural & creative, education, aerospace, such as Guangzhou Automobile, Dongfeng Motor, Gree Group, LG Electronics, TTI, Fohan Service Bureau, Tongji University, Southern University of Science and Technology, University of Texas at Austin, and Massey University Auckland.

Polymer Powder | Wide Variety

There are many types of polymer powders that can be directly used for 3D printing.

ABS has good hot melt and impact strength, and is the preferred engineering plastic for fused deposition 3D printing technology. It is used after powdering, and its application range covers almost all daily necessities, engineering supplies and some mechanical supplies.

PA powder is the most used and successful material in SLS printing technology. With its own excellent properties and modification properties, it has its presence in industrial manufacturing and daily life.

PEEK has the characteristics of excellent wear resistance, biocompatibility, chemical stability, and Young's modulus that is closest to human bone. It is an ideal artificial bone replacement material and is suitable for long-term implantation in the human body.

Others, in addition, there are various PCL, PP, PAK, etc., which are also polymer powders that can be directly 3D printed. You can choose according to your own needs.

Classification/category of Polymer powder

Classification of Polymer powder:

Plastic polymers, thermoset polymers and polymer composites. Commonly used thermoplastic materials for 3D printing include polystyrene (PS), polyurethane (TPU), polyetheretherketone (PEEK), polypropylene (PP), ABS, nylon (PA), and more. The currently developed polymer composites mainly include particle-reinforced polymer composites, fiber-reinforced polymer composites and nanocomposites.

What Makes Our Polymer Powder Special?

Thermoplastic products even outperform metals in weight and stiffness ratios in some cases. In certain applications, 3D printed high-performance thermoplastics can replace aluminum alloys. Thermoplastic 3D printing materials are widely used, such as medical implants (PEEK), sports shoe soles (TPU), automotive functional parts (PA), precision casting (PS), etc.

What Are the Advantages of Polymer Powder?

As one of the most advanced technology, polymer powder 3D printing has many advantages such as high materials utilization rate, free of support structure, great design freedom, and large available materials, which has shown great potential and prospects in various industry applications.

User Reviews

What users say about TPM 3D printing

Frequently Asked Question

Do you have any question?

Located in the Big Data Industrial Park of Yannan High-tech Zone, Jiangsu Province, the TPM 3D Asia Exhibition and Training Center and the SLS Advanced Materials Printing Center (referred to as the Center), covering an area of more than 1,000 square meters, vow to promote the research and development of TPM3D advanced materials and innovative industry applications.

TPM 3D is a Chinese enterprise specializing in R&D and manufacturing of SLS selective laser sintering additive manufacturing equipment and providing professional 3d printing services.

The TPM 3D technical team has been engaged in industrial 3D printing business since 1999, and has become an industry brand focusing on 3D printing in the past 20 years.

TPM3D is a professional R&D and manufacturer of SLS 3D printing systems, which can customize SLS printing equipment and provide efficient and fast 3D printing services.

TPM3D mainly develops and manufactures SLS 3D printing system, our printing equipment can support more than 20 kinds of printing materials, including PA12, PA11, PA6X, TPU, PP, PEEK, etc.

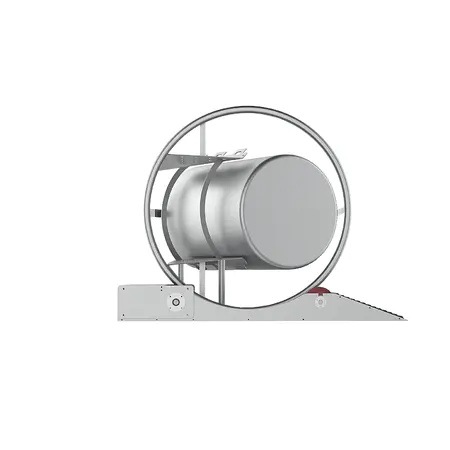

Among the SLS printing equipment currently launched by TPM3D, the S600DL dual-laser SLS 3D printing system is the equipment with the largest forming size among the current similar printing equipment, and the size of the forming cylinder reaches 600mm*600mm*800MM.

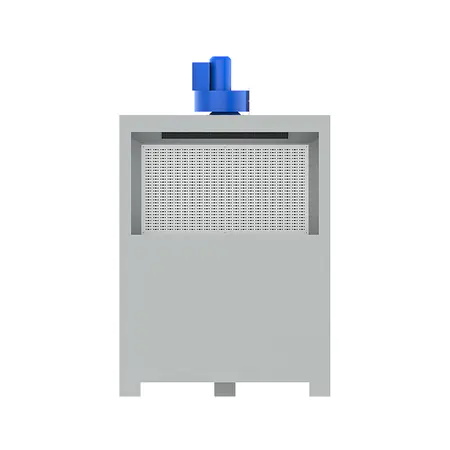

Among TPM3D's market-oriented printing equipment, S320HT is an SLS 3D printing equipment for high-temperature molding materials.