Features

Why Choose TPM 3D printing?

TPM 3D Asia Advanced Materials Printing Center

TPM 3D Asia advanced materials printing center located in Jiangsu Province, cover the area with more than 1000 m2. The center consists of intelligent manufacturing 3D printing display platform, industrial and advanced materials intelligent printing center, medical sterile R&D experiment labs, and SLS post processing center and multimedia conference zone.

3D Printing Digital Medical Center

The center construction includes three phases, we can provide orthopedic insoles, orthopedic pillows, scoliosis braces, knee orthoses, application of surgical guides for head, pelvis, spine and knee joints and 3D printing of braces, as well as orthopaedic standardized implant products development.

Our research

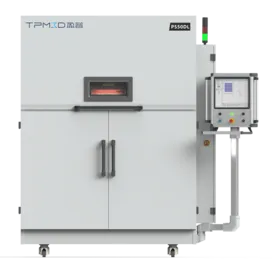

TPM3D has successfully developed 10+ laser sintering additive manufacturing systems, and more than 10 kinds of polymer powder printing material for high-quality parts manufacturing, has more than 30 national patents as well.

We Have The Best Solutions for Your Business

TPM3D technical team has been engaged in industrial 3D printing business since 1999 and has become the industry brand with 20 years focusing on 3D printing service。

TPM3D has various customers at home and abroad from the fields of automobile, electrical appliances, electronics, medicals, cultural & creative, education, aerospace, such as Guangzhou Automobile, Dongfeng Motor, Gree Group, LG Electronics, TTI, Fohan Service Bureau, Tongji University, Southern University of Science and Technology, University of Texas at Austin, and Massey University Auckland.

Large SLS Printers, The Next Generation of Manufacturing

The new generation of manufacturing technology known as large SLS printers is revolutionizing the way that we make products. This printer has a large build volume, which allows the creation of complex and large parts that were previously impossible to make using traditional manufacturing techniques.

What is a Large SLS Printer and How Does It Work?

Large SLS printers, a type 3D printing technology, use a powerful laser to melt and fuse powdered materials layer by layer until they form a 3D object. This printer has a higher build volume than other SLS printers. This allows the creation of more complex parts and larger parts in one print job. Large SLS printers are able to use a variety of materials including ceramics and metals. This makes them versatile tools for manufacturing.

The Advantages of Large SLS Printers in Manufacturing

Large SLS printers are able to produce parts with complex and intricate geometries, which is a key advantage in modern manufacturing. Large SLS printers are a great tool for industries like aerospace, automotive, medical, and other areas where precision and accuracy is critical. Large SLS printers are capable of producing functional prototypes, low volume production parts, or even end-use components.

Different Industries Use Large SLS Printers

SLS printers of large size are used in many industries such as aviation, medical, and automotive to produce high-performance, durable parts. Large SLS printers are used in aerospace to produce parts for aircraft that need to be lightweight and durable. Large SLS printers are used in the automotive industry to produce engine components, exhaust systems, dashboards, and other parts. They must be strong, lightweight, and capable of enduring high temperatures and vibrations. Large SLS printers can be used in the medical sector to produce custom prosthetics, implants and surgical instruments. They must be biocompatible, sterilized, and capable of withstanding the stresses placed on the body.

Limitations and challenges of large SLS printers

Large SLS printers have their advantages but also some drawbacks. They are expensive to buy and maintain and require special knowledge. To ensure quality printed parts, they require high power and controlled conditions.

Future of Large SLS Printers and Manufacturing

It is exciting to see the future of large SLS printers, and manufacturing. The technology is evolving and becoming more accessible. It has the potential for revolutionizing the manufacturing industry. Large-scale SLS printers are able to reduce waste, improve efficiency, and create more complex, sustainable products.

Large SLS printers can be powerful and versatile tools for producing complex and large parts with high precision. While they have many benefits and can be used in various industries, there are also some challenges and limitations. Large SLS printers are poised to revolutionize the way we make products and change the direction of manufacturing.

Featured Products

Collection about TPM 3D printing

User Reviews

What users say about TPM 3D printing

Frequently Asked Question

Do you have any question?

SLS technology is used for selective laser sintering of powdered materials to create 3D objects with complex geometries.

Large SLS printers can be expensive and require specialized knowledge to operate.

SLS printers with large dimensions are used in many industries, including aerospace, automotive, medical, and other areas that require large, complex parts with high precision.

The advantage of using a large SLS printer is the ability to print larger and more complex parts in a single print job.

Large SLS printers can print parts with a wide range of materials, including plastics, metals, and ceramics.

Our updates and blog posts

3D printer product prototype design verification advantages

Validation advantages in 3D printer product prototyping 5. Speed up the design process. Speed up testing progress. 3D printing is an economical option. Diversity of 3D printing technologies. High degree of design freedom

Key elements for 3D printing technology to go carbon neutral

The key elements for 3D printing technology to become carbon neutral are, materials, manufacturing, transportation, use, and recycling

Understanding of Design for Additive Manufacturing (3D Printing)

The benefits of design for additive manufacturing lie in design freedom, adaptability and flexibility, streamlining the entire supply chain, adding value, saving time and money.