A Brief History of SLS industrial printers

Selective laser sintering (SLS)was developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beaman. Much like other 3D printing technologies, SLS is an additive manufacturing method that uses a high-powered laser to “sinter” or solidify a powdered plastic material. The same concept has since been modified to work with various materials including metals, glass, and ceramics.Since the invention of sls printing technology, it has been applied in the industrial field, initially restricted for use in rapid prototyping and low-volume production of custom parts. The use of high-powered lasers and handling of powder material have proven to be either too dangerous or too expensive to be scaled down with practical costs. However, with the continuous development of technology and the needs of life and production, sls printing technology has gradually used from prototype manufacturing to the application of end products.

Types of SLS 3D Printers

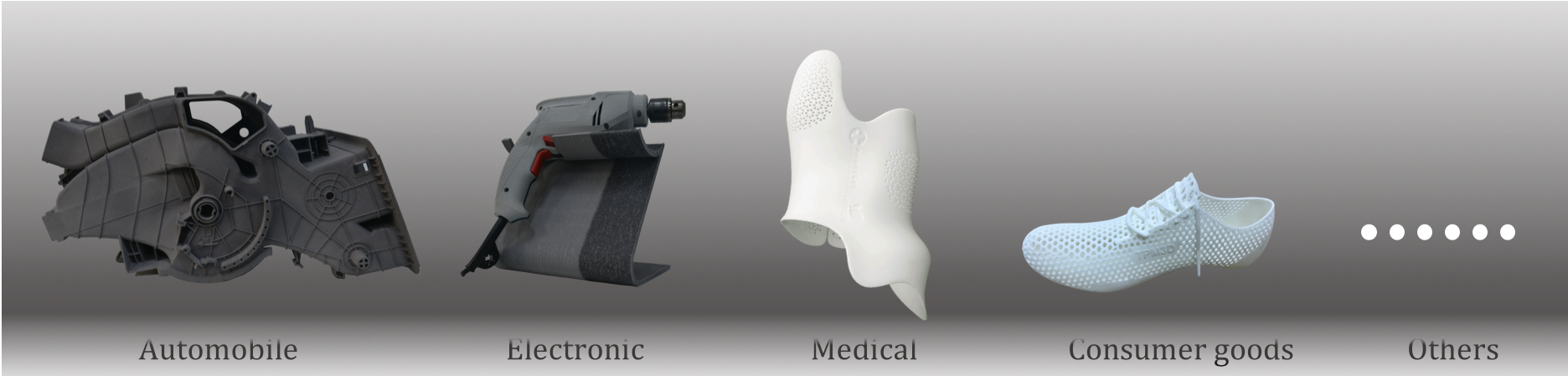

The consumer-grade SLS 3D printer is a product that has only appeared in recent years. It is small in size, flexible in operation, and low in equipment prices. It is more suitable for individual consumers to make some customized artistic and creative products. Industrial-grade SLS 3D printers have a long history. They have been used in the industrial field since the emergence of SLS printing technology in the 1980s. After decades of technical iterations, there has been great progress in both technology and materials. Mature technology and more and more abundant printing materials make the application of industrial SLS printers develop from the initial prototype manufacturing to the current end product application, which meets the needs of individual customized products and the needs of enterprise R&D products and mass production.

SLS Industrial Printer Applications

SLS Industrial Printer Benefits

Selective laser sintering is the most common additive manufacturing technology for industrial applications, trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.SLS printing technology has the following advantages: No need for support structures;Fast; Excellent layer adhesion; Ideal for dyeing.

The role of SLS industrial printers

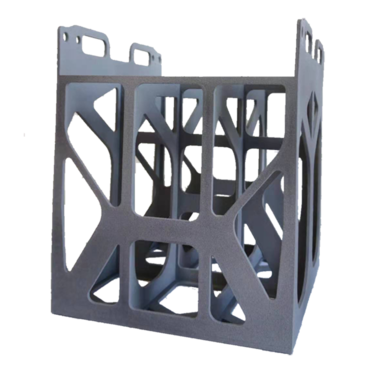

Industrial SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

Given its robustness and ability to produce highly complex parts, SLS can save significant time and cost for small batches of parts that would otherwise need to be assembled by traditional manufacturing. SLS is the perfect combination of function, strength and sophistication. SLS is particularly effective for mass customization of certain low-volume end-use parts without the need to worry about costly and inefficient tooling or retooling. Since SLS parts are able to withstand wear and environmental conditions, this technology can reduce the production volume of parts. Like other additive manufacturing technologies, SLS allows parts and molds to be stored digitally, using data that will never corrode, be lost in transit, or require expensive storage space. Even if original parts are not available, designs are always available and can be produced as needed.

.png)