Foreword:

Formula Student China is a platform for training and selecting outstanding automotive talents. It has set up three events: Formula student Combustion China (FSC), Formula student Electric China (FSEC) and Formula student Autonomous China (FSAC). As the leading manufacturer of SLS 3D printing equipment in China, TPM3D has sponsored the race for three consecutive years, hoping that the younger generation will have more opportunities to know more about 3D printing technology. In 2021, TPM3D sponsored the driverless team of Beijing Institute of Technology and Tongji University Racing Team. Today, let’s learn about the SLS 3D printing applications in different racing cars.

Formula Student China is a platform for training and selecting outstanding automotive talents. It has set up three events: Formula student Combustion China (FSC), Formula student Electric China (FSEC) and Formula student Autonomous China (FSAC). As the leading manufacturer of SLS 3D printing equipment in China, TPM3D has sponsored the race for three consecutive years, hoping that the younger generation will have more opportunities to know more about 3D printing technology. In 2021, TPM3D sponsored the driverless team of Beijing Institute of Technology and Tongji University Racing Team. Today, let’s learn about the SLS 3D printing applications in different racing cars.

About The Beijing Institute of Technology Driverless Racing Team:

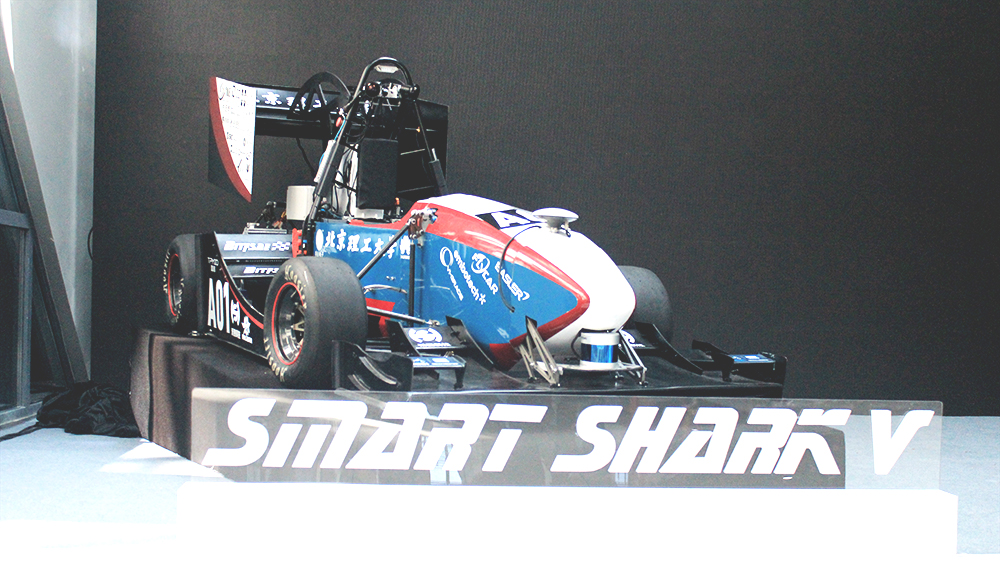

Founded in 2007, The Beijing Institute of Technology Driverless Racing Team (BITFSD) independently designed and manufactured the world's first driverless college student formula racing car in 2016, and won the championship in the 2017, 2018 and 2020 seasons. It is the only "triple champion" of the formula race in Chinese universities.

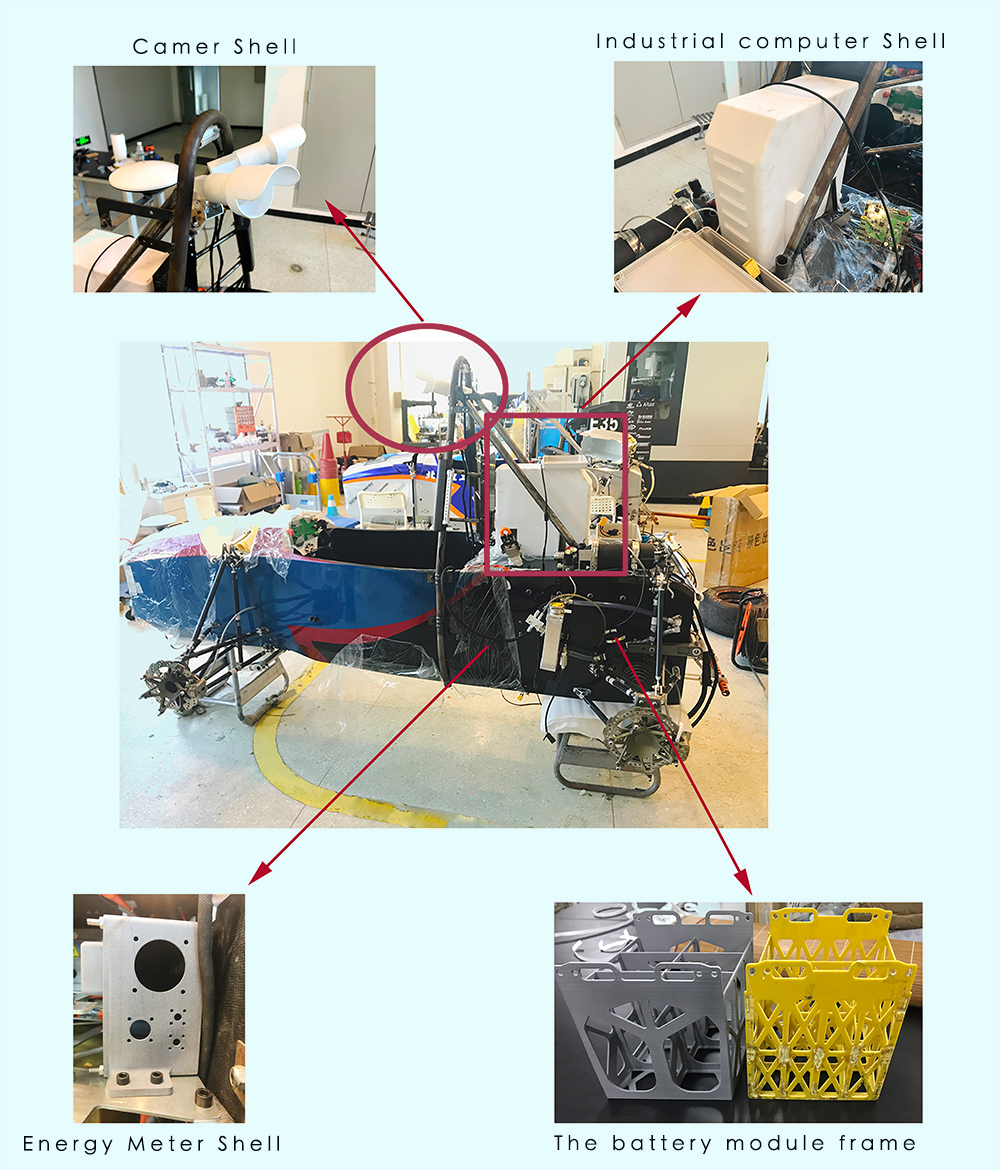

In 2021, TPM3D sponsored BITFSD SLS 3D printing parts covering in five categories, including low-voltage box shell, high-voltage box shell, energy meter shell, flame-retardant battery module frame and industrial computer shell, which are distributed in the electronic control system, energy system, braking system and body of the racing car. It effectively reduces the racing car’s weight and improve the performance and safety.

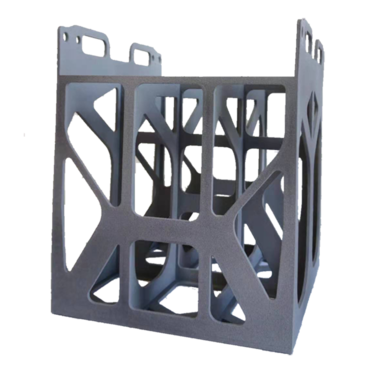

The battery module is the energy core of the racing car. In the past, BITFSD used glass fiber board bonding to make the module frame. In 2021, they use TPM3D’s Precimid1171 FR (PA12) material instead, this flame retardance material passed UL94V0,and has best surface and resistance characteristics, so that the battery module can be better protected and the weight is reduced nearly 37%.

Every racing car has an energy meter to ensure the power is under 80KW to keep safe. For the energy meter shell, BITFSD uses TPM3D’s Precimid1172Pro GF30 (PA12) material to print. Due to the addition of 30% glass fiber, the shell has excel––ent mechanical properties, wear resistance and impact resistance. At the same time, the thermal deformation temperature reaches 184 ℃ (@ 0.45Mpa), which can accomplish this task well.

TPM3D’s Precimid1172Pro (PA12) material is used to print the industrial computer shell and camera shell, which has the characteristics of light weight, good toughness and excellent comprehensive performance. It not only protects the industrial computer and camera, but also reduces the weight of the racing car, making the racing car safer and faster!

In the end , we wish the BITFSD another success in the new season!