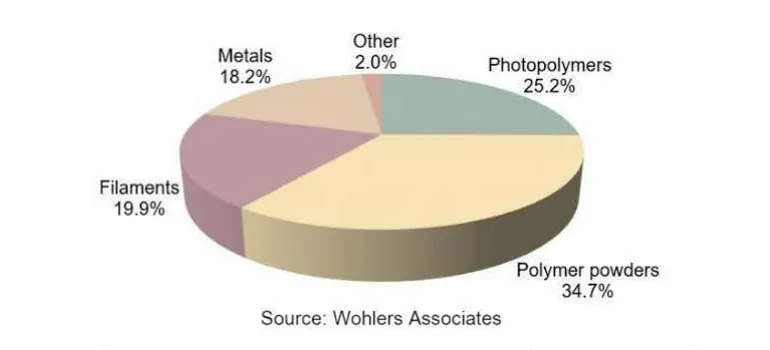

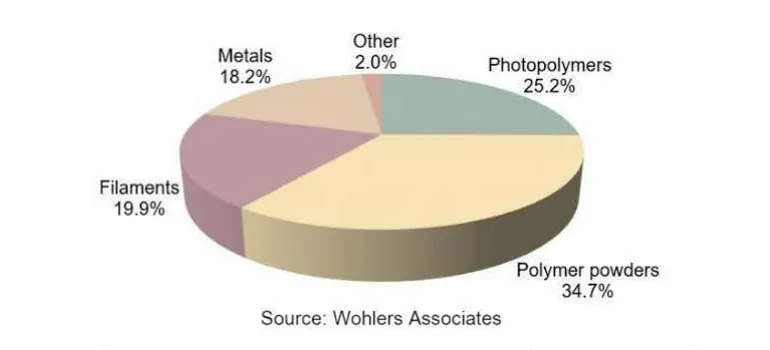

In 2021, the percentage of polymer powder products in the worldwide 3D printing material market has gone beyond photosensitive material for the very first time (source: Wohlers Record), and nylon has slowly become one of the most successful product category among printing provider.

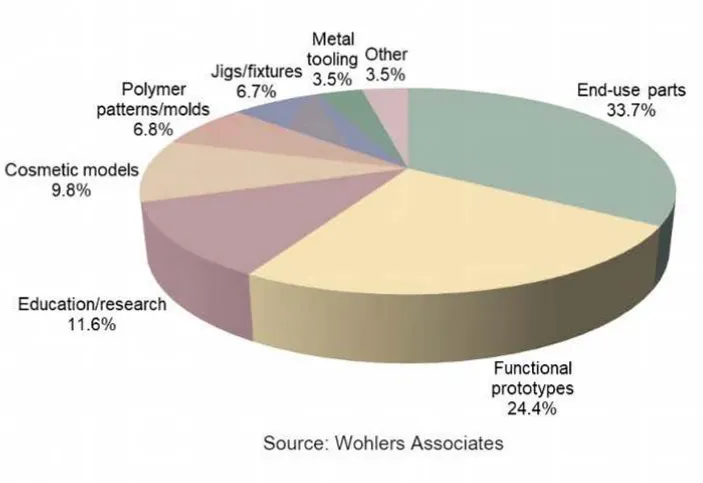

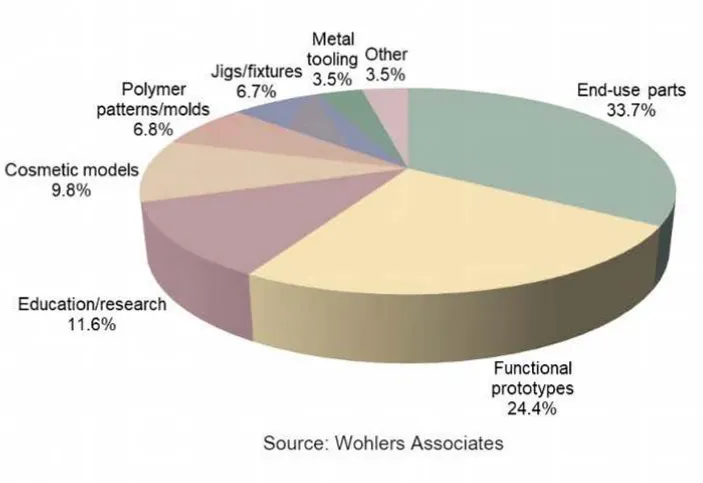

At the same time, in regards to applications, we can likewise see that amongst all application groups of 3D published models, the percentage of end-use components rates first (34%), surpassing making use of practical models (24%), showing that the marketplace and individuals' expectations for 3D printed designs are no longer limited to create confirmation, yet to be straight utilized as final products.

At the same time, in regards to applications, we can likewise see that amongst all application groups of 3D published models, the percentage of end-use components rates first (34%), surpassing making use of practical models (24%), showing that the marketplace and individuals' expectations for 3D printed designs are no longer limited to create confirmation, yet to be straight utilized as final products.

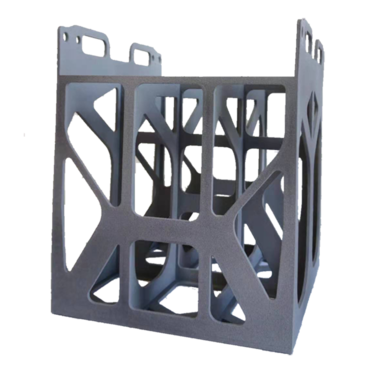

The above data show the current trend in the 3D printing industry - 3D printing technologies that can manufacture end products will certainly experience rapid advancement. Especially SLS 3D printing modern technology, which is currently one of the most appropriate for mass-producing non-metallic items, is swiftly expanding and broadening its proportion in the printing service industry. A growing number of prototyping producers are purchasing SLS tools, incorporating nylon printing solutions right into their company extent.

The above data show the current trend in the 3D printing industry - 3D printing technologies that can manufacture end products will certainly experience rapid advancement. Especially SLS 3D printing modern technology, which is currently one of the most appropriate for mass-producing non-metallic items, is swiftly expanding and broadening its proportion in the printing service industry. A growing number of prototyping producers are purchasing SLS tools, incorporating nylon printing solutions right into their company extent.

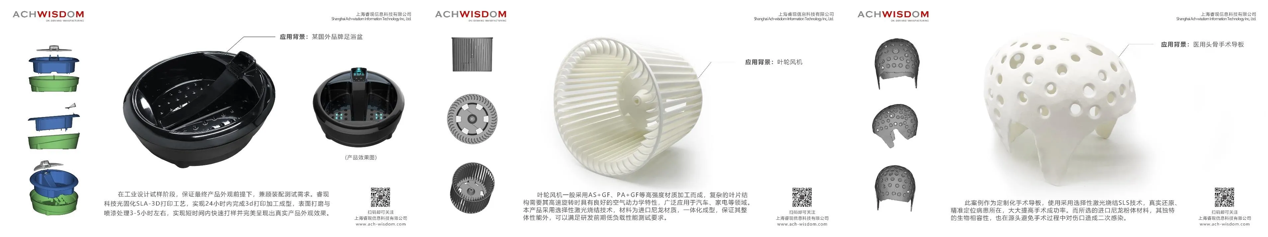

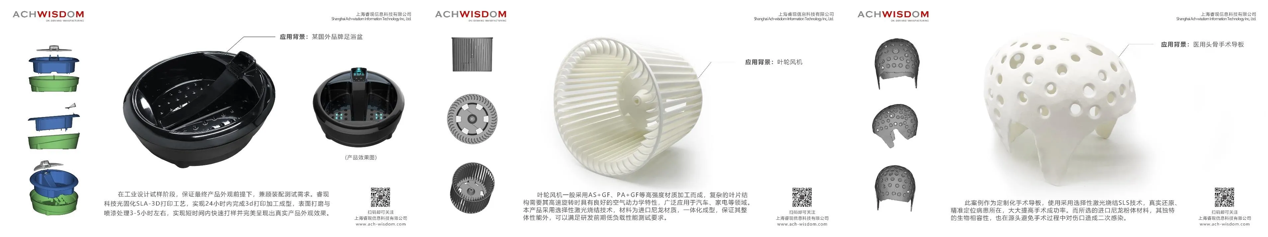

As early as 2016, ACHWISDOM first bought TPM3D’s SLS printer improve the prodution. With the continuous maturity of innovation and the continuous increase in market demand in the last few years, ACHWISDOM has regarded SLS innovation as a brand-new development point and breakthrough in its service, and grew the cooperation with TPM3D by purchasing numerous industrial-grade SLS systems, consisting of 4 TPM3D P360 and 2 part & powder processing station(PPS). ACHWISDOM, as a modern service-oriented venture, suggests the concept of "on-demand production" and is dedicated to providing electronic on-demand manufacturing solutions from idea to item for residential and international consumers, meeting their low-cost validation and "develop-measure-know" responses cycle, and achieving the minimum sensible item's market promo demand. At the same time, it combines traditional manufacturing with additive production, with solutions covering 3D scanning, 3D printing, machining, sheet metal production, mold production, and so on.

ACHWISDOM, as a modern service-oriented venture, suggests the concept of "on-demand production" and is dedicated to providing electronic on-demand manufacturing solutions from idea to item for residential and international consumers, meeting their low-cost validation and "develop-measure-know" responses cycle, and achieving the minimum sensible item's market promo demand. At the same time, it combines traditional manufacturing with additive production, with solutions covering 3D scanning, 3D printing, machining, sheet metal production, mold production, and so on.

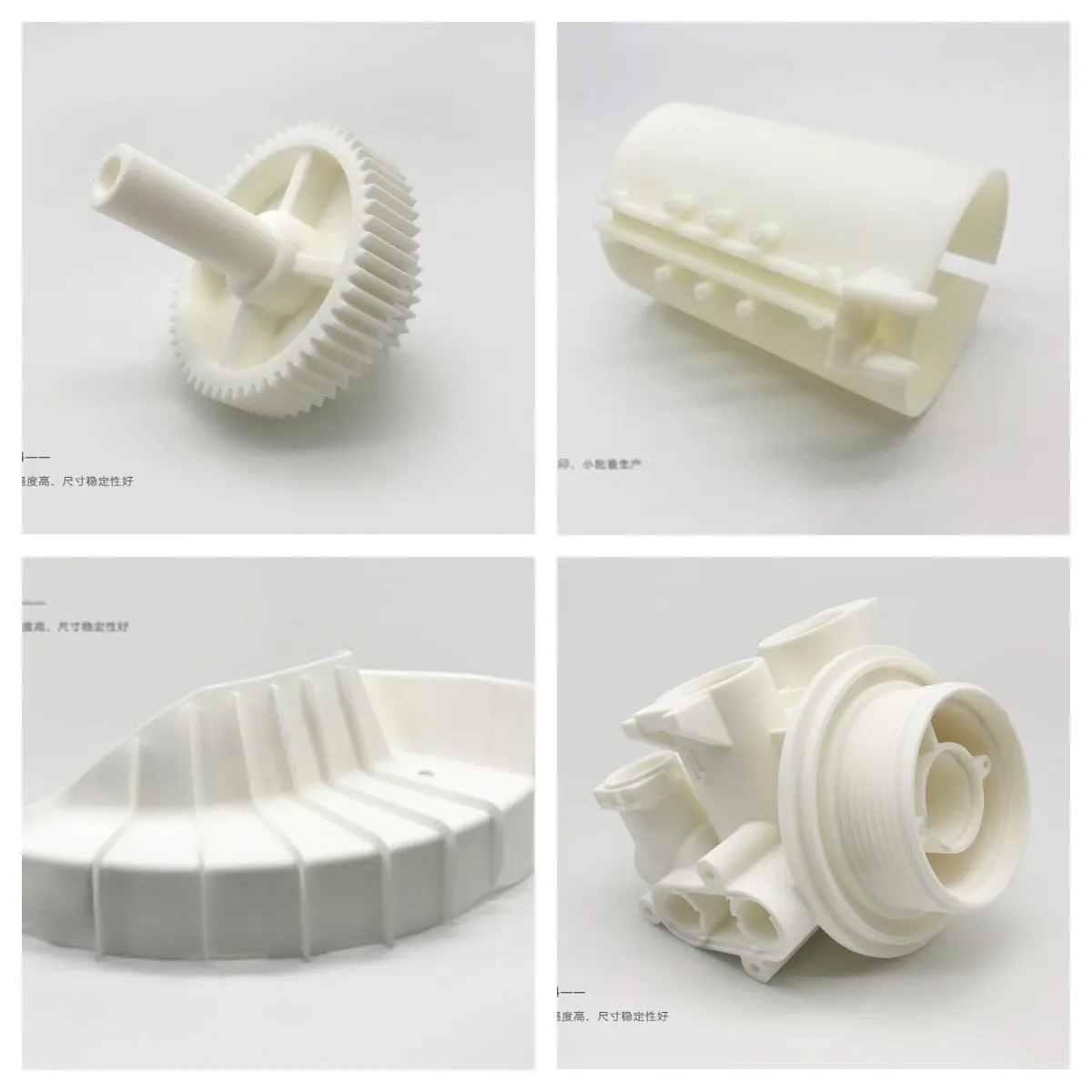

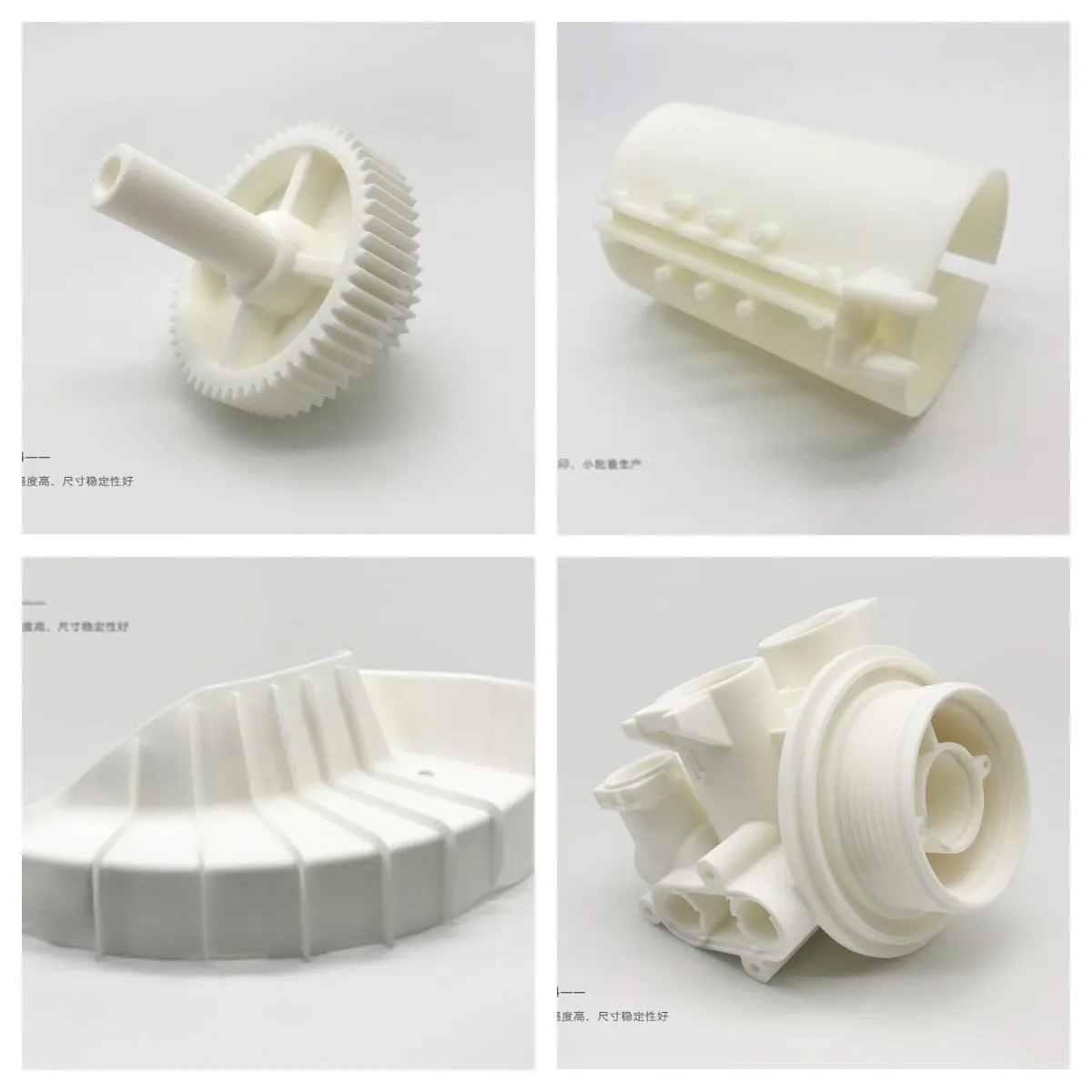

ACHWISDOM focuses on product top quality and application development. It has actually given over a million products/parts, offering industries consisting of automotive, aerospace, consumer electronics, medical, education and creation, etc. It has established lasting teamwork partnerships with lots of well-known domestic and international business and establishments, such as Commercial Aircraft Firm of China, China Aerospace Science and Industry Company, Bosch, Honeywell, Magna, Tongji College, Shanghai Jiao Tong College, China College of Mining and Technology, Chinese Academy of Sciences, and so on. The following showcases some superb products printed by ACHWISDOM.

ACHWISDOM focuses on product top quality and application development. It has actually given over a million products/parts, offering industries consisting of automotive, aerospace, consumer electronics, medical, education and creation, etc. It has established lasting teamwork partnerships with lots of well-known domestic and international business and establishments, such as Commercial Aircraft Firm of China, China Aerospace Science and Industry Company, Bosch, Honeywell, Magna, Tongji College, Shanghai Jiao Tong College, China College of Mining and Technology, Chinese Academy of Sciences, and so on. The following showcases some superb products printed by ACHWISDOM.

These nylon parts showcased were all produced by the 4 P360 from TPM3D and have outstanding precision, strength, and surface area quality. The creating cylinder size of P360 is 360 × 360 × 600mm, furnished with imported high-performance CO2 laser, with a printing layer density of 0.06-0.3 mm, taking both molding accuracy and manufacturing effectiveness right into factor to consider. It embraces an incorporated control system with a smaller sized impact, superb safety and security, and stability. It is an affordable additive manufacturing system with excellent detailed efficiency.

These nylon parts showcased were all produced by the 4 P360 from TPM3D and have outstanding precision, strength, and surface area quality. The creating cylinder size of P360 is 360 × 360 × 600mm, furnished with imported high-performance CO2 laser, with a printing layer density of 0.06-0.3 mm, taking both molding accuracy and manufacturing effectiveness right into factor to consider. It embraces an incorporated control system with a smaller sized impact, superb safety and security, and stability. It is an affordable additive manufacturing system with excellent detailed efficiency.

For part cleaning and powder recycling management, ACHWISDOM has equipped these 4 P360 with 2 sets of TPM3D all-in-one part powder full performance processing workstations PPS, which can provide part cleaning, powder mixing, and automatic online powder supply for 2 P360 simultaneously. It can effectively suppress the dust generated during the part cleaning process, with a high degree of intelligent automation, helping users improve processing efficiency and reduce labor input.

For part cleaning and powder recycling management, ACHWISDOM has equipped these 4 P360 with 2 sets of TPM3D all-in-one part powder full performance processing workstations PPS, which can provide part cleaning, powder mixing, and automatic online powder supply for 2 P360 simultaneously. It can effectively suppress the dust generated during the part cleaning process, with a high degree of intelligent automation, helping users improve processing efficiency and reduce labor input.

As early as 2016, ACHWISDOM first bought TPM3D’s SLS printer improve the prodution. With the continuous maturity of innovation and the continuous increase in market demand in the last few years, ACHWISDOM has regarded SLS innovation as a brand-new development point and breakthrough in its service, and grew the cooperation with TPM3D by purchasing numerous industrial-grade SLS systems, consisting of 4 TPM3D P360 and 2 part & powder processing station(PPS).