Introduction

This article will discuss the revolutionary printing technology of SLS 3D printing from its evolution to its future potential in changing various industries' manufacturing processes.

Discovering the Future of SLS 3D Printing and Its Impact on Industries

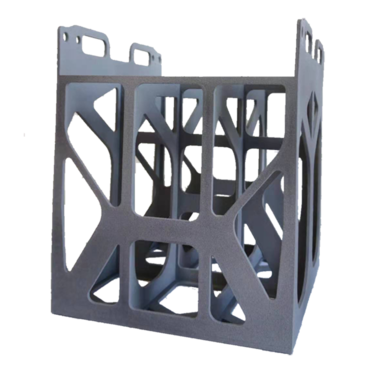

SLS 3D printing, also known as Selective Laser Sintering 3D printing, is a groundbreaking technology that has been making waves in various industries. This technique involves using high-powered lasers to selectively sinter powder materials into a 3D object. Unlike traditional 3D printing methods, SLS does not require support structures, allowing for more complex designs and geometries. In this article, we will explore the evolution of SLS 3D printing, its applications across different industries, its advantages and limitations, as well as its potential future impact.

The Evolution of SLS 3D Printing

Since its inception in the 1980s, SLS 3D printing has made significant progress. The first-ever SLS printer was developed by Dr. Carl Deckard and Dr. Joe Beaman at the University of Texas at Austin. Initially used for rapid prototyping and tool fabrication purposes only; over the years, it has expanded to various industries including aerospace, automotive medical fashion architecture.

Advancements in SLS technology have resulted in faster print speeds and improved accuracy. The use of multiple lasers and scanners has increased print speeds while developments in software algorithms have enhanced precision and resolution capabilities for printed objects. Current state-of-the-art SLS printers can effortlessly produce intricate designs with complexity.

Discovering Applications of SLS 3D Printing Across Industries

SLS is widely applicable across numerous industries. In aerospace industry- lightweight durable parts are produced using this method which allows for creating parts with complex geometries that conventional manufacturing methods cannot achieve.

In automotive industry- SLS 3D printing is used for rapid prototyping and tool fabrication. This technology enables quick production of parts and tools, reducing manufacturing time and costs. In the medical field, SLS 3D printing is utilized to manufacture prosthetics and implants. The ability to design custom-fitted products tailored to individual patients has revolutionized the medical industry.

The fashion industry has also taken notice of SLS 3D printing. Designers are using this technique to create intricate and unique pieces that would be impossible with traditional manufacturing methods. SLS allows for the creation of complex geometries and designs, giving designers the freedom to explore new possibilities.

In architecture, SLS 3D printing is used for producing models and prototypes. This technology enables the creation of detailed and accurate models, allowing architects and designers better insights into their designs.

Advantages of SLS 3D Printing

SLS 3D printing offers several advantages over traditional manufacturing methods. One major advantage is cost-effectiveness- eliminating the need for expensive molds or tools reduces production costs significantly. The ability to produce parts on-demand also reduces inventory requirements further lowering costs.

Customization is another benefit offered by SLS; the capability to create complex geometries/designs facilitates production of customized parts/products which holds particular importance in fields requiring personalized prosthetics/implants.

Time efficiency is another advantage; on-demand part production reduces lead times required in manufacturing processes being crucial in industries where timeliness matters such as aerospace or automotive sectors.

SLS 3D printing also minimizes waste- unlike traditional methods that often generate substantial amounts of scrap material; only materials required for part fabrication are utilized thereby reducing waste generation while conserving resources.

Challenges & Limitations of SLS 3D Printing

Despite offering numerous advantages, there are challenges & limitations associated with SLS 3D printing due to factors like materials availability/constraints concerning design complexity/post-processing options etc., which restrict its applications in certain industries.

The Future of SLS 3D Printing

SLS 3D printing is a revolutionary technology with potential to transform various industries. While it faces challenges and limitations, its unique advantages make it highly competitive against traditional manufacturing methods. As technology continues to advance, improvements in print speed and accuracy are expected, expanding the scope of applications even further.