Yingpu's old fans should have paid attention to the relevant reports of "Yingpu Helps 2019 College Student Formula" as early as last year. Yes, as early as the beginning of June last year, Yingpu Xiaobian participated in the initial design and printing of the intake hose and pressure stabilization cavity of the Jiaotong University racing team, and this year Yingpu will video this process (like the less mature original, more intuitively show you the design and production process of Sls 3d Printing Automotive | SLS 3D printing pressure stabilization cavity.

Before clicking on the video, let's take you to introduce the previous situation review of this racing regulator:

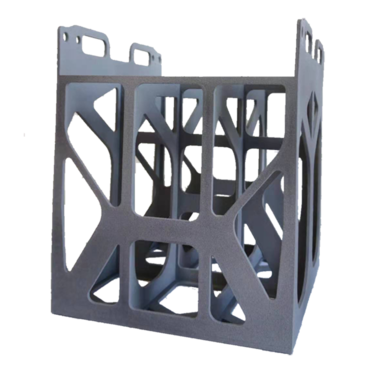

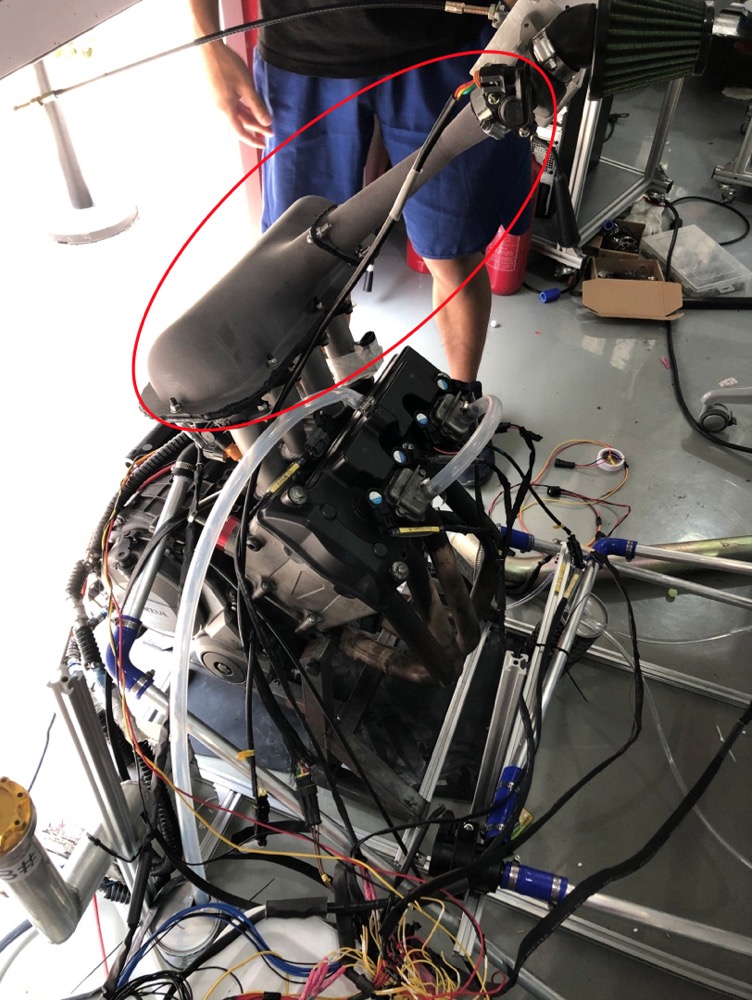

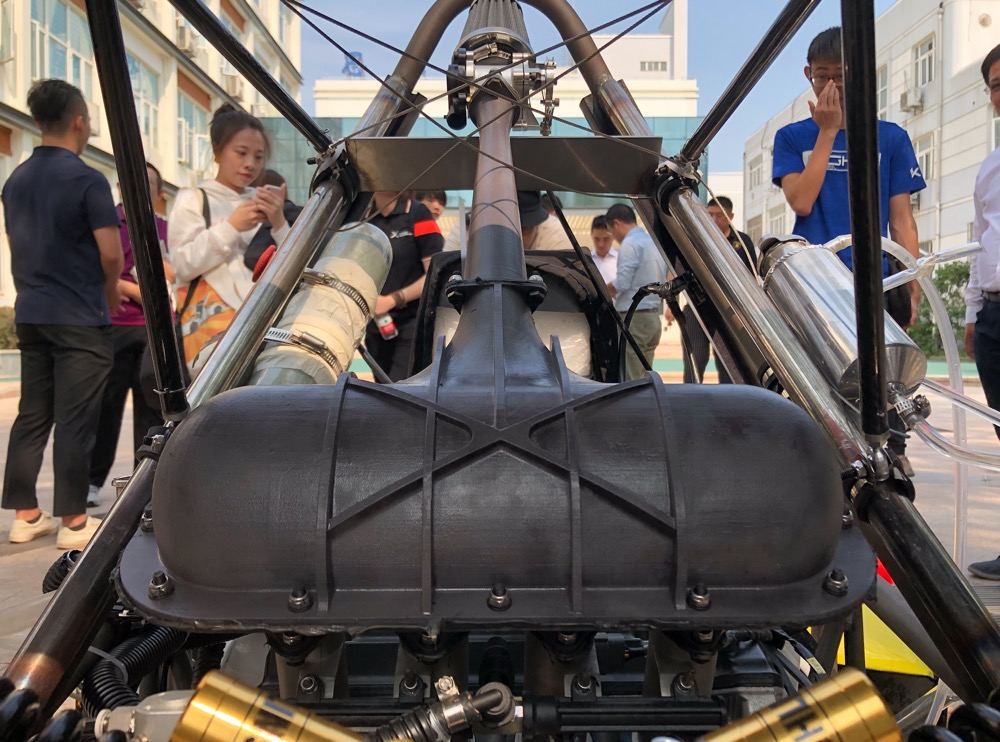

Just as all the original design will not be nearly perfect, Xiaobian has the honor to represent the technical support of TPM3D Yingpu into the laboratory of the racing team student innovation center, after the exchange learned that the printed initial pressure stabilizer cavity will appear slight deformation after the engine is accelerated, after further discussion and analysis, it is learned that the components at the beginning of the design overconsidered the weight reduction factors, ignoring the engine performance and the change factors of the pressure chamber structure, the wall thickness of the overall component is reduced to 1/ 2, which in turn leads to insufficient rigidity of parts. After clarifying the reason, the two parties finalized the plan on the spot, the power group of the racing team started from the design side to improve the rigidity of the parts, and the TPM3D Yingpu adapted the appropriate solution from the material and process side. With the joint efforts of both parties, the second-generation design of the intake pressure regulator cavity was soon born, the power pack improved the rigidity of the first generation design parts through external stiffeners, etc., TPM3D Yingpu adapted to the high rigidity glass fiber nylon Precimid1172Pro GF30 BLK material printing with Yingpu's unique parts strengthening processing process, under multiple guarantees, the second-generation intake pressure regulator cavity components successfully passed the engine bench test and vehicle road test. At the 2018 new car launch, the vehicle was equipped with a second-generation regulator cavity assembly.

Above: Close-up of the body of the new car printed by TPM Yingpu of the intake regulator cavity and intake hose assembly | Sls 3d Printing Automotive