Selective Laser Sintering (SLS), SLS procedure resembles stereolithography device (RUN-DOWN NEIGHBORHOOD), yet SLS generally takes on infrared laser beam of light, and the product likewise becomes powder granular product from photosensitive resin product.

SLS process has many molding products is very easy to sustain, consisting of variouspowder products with various mechanical properties and different nylon mixed materials. Such as light weight aluminum powder and nylon blended products ideal for moulds, carbon fiber and nylon blended materials with very light weight and solid mechanical residential or commercial properties, different plastic mixed materials and ceramic products, and so on. In theory, any kind of fusible powder can be used to produce items or designs, so the selection of powder materials is among the primary advantages of SLS innovation.

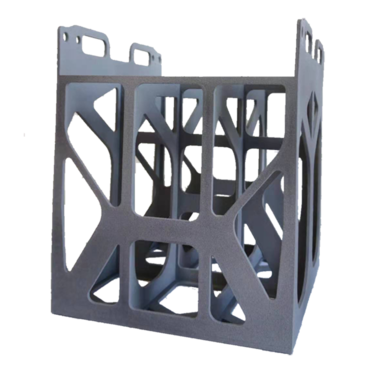

The printing rate is fast and can print any kind of complex structure;

High reusability, which is typically 80% (our business maximizes the process optimization, making the reusability of materials can get to greater than 85%).

SLS process has many molding products is very easy to sustain, consisting of variouspowder products with various mechanical properties and different nylon mixed materials. Such as light weight aluminum powder and nylon blended products ideal for moulds, carbon fiber and nylon blended materials with very light weight and solid mechanical residential or commercial properties, different plastic mixed materials and ceramic products, and so on. In theory, any kind of fusible powder can be used to produce items or designs, so the selection of powder materials is among the primary advantages of SLS innovation.

The printing rate is fast and can print any kind of complex structure;

High reusability, which is typically 80% (our business maximizes the process optimization, making the reusability of materials can get to greater than 85%).