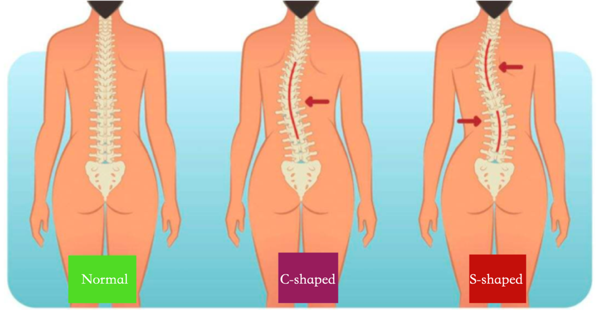

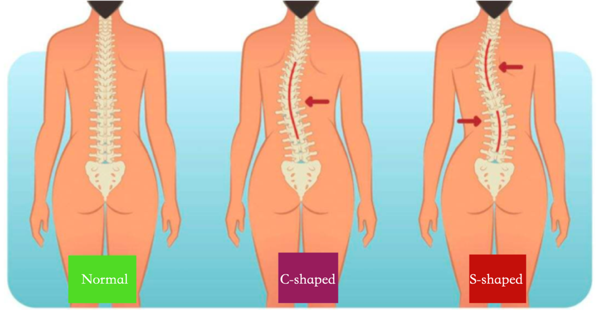

Scoliosis can be divided into two main categories: Non-structural and Structural. Non-structural refers to temporary scoliosis caused by some reasons, once the cause is removed, it will be recovered, but long-term existence patient may also develop into structural scoliosis.

There are many causes of structural scoliosis, among which idiopathic scoliosis is the most common, accounting for 75% to 85% of the total, and adolescent idiopathic scoliosis is the most common.

The treatment of scoliosis includes surgical treatment and non-surgical treatment, which should depend on the degree of spinal deformity, age, trunk balance and other factors. In general, the patient whose scoliosis angles between 20 and 40 degrees or adolescents whose scoliosis progress more than 5 degrees per year need the conservative treatment. At present, brace therapy is the most common use in conservative treatment.

Manufacturing process of traditional scoliosis orthosis:

The traditional orthosis is generally made by gypsum molding, repairing, thermoplastic plate attachment, cutting, polishing and installation of lining ties, with the advantages of relatively low price and capability of re-heat and trim. The disadvantage is that the whole process is relatively cumbersome, the gypsum molding needs the participation of patients, which reduces the experience of patients, and the production efficiency is low - an orthotist can make braces for 3-5 patients a day at most. In addition, traditional orthoses are large in size and difficult to hide, which has a great impact on the normal study and life of adolescents.

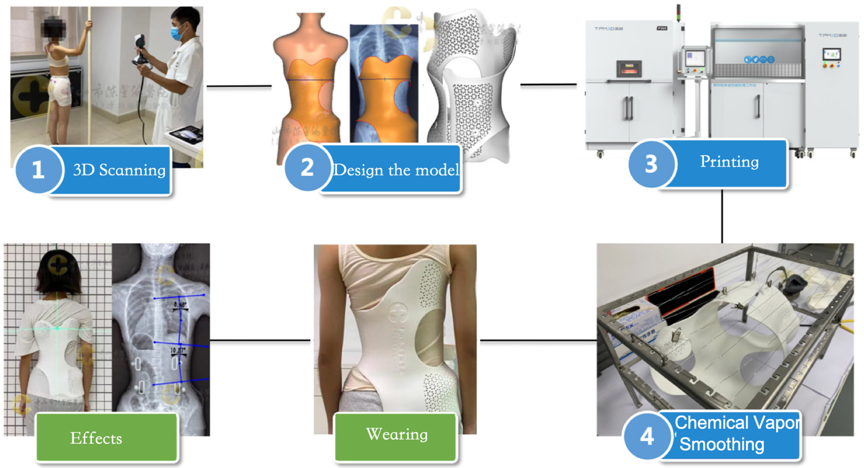

The process of making scoliosis orthosis by 3D scanning and 3D printing technology:

In 2021, the 3D Printing Digital Medical Center was set up in Zhongshan Chenxinghai Hospital, relying on TPM3D's laser sintering 3D printing technology, it manufactures customized health care and rehabilitation products to provide precise medical solutions for patients.

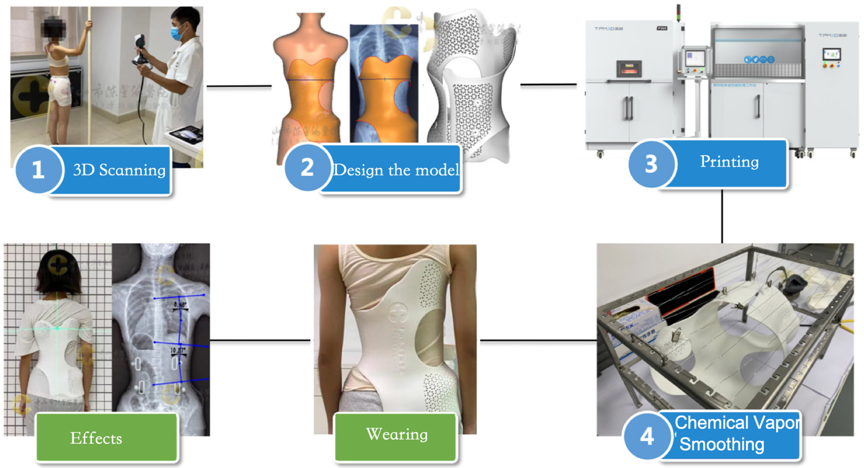

Let's take a practical case of Chenxinghai Hospital to understand how we use 3D printing technology to make scoliosis orthosis:

Patient's condition: a 13-year-old girl, thoracic scoliosis 15 °, lumbar scoliosis 23 °, the degree of scoliosis increased year by year.

Treatment: Wear nylon 3D printed scoliosis orthosis.

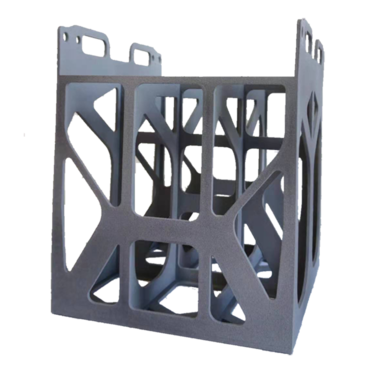

The process: Firstly, performing 3D scanning on a patient to get her data; Then, designing and modifying the model based on the required data, so as to ensure the comfort of the patient when wearing and achieve the effect of orthopedics to the maximum extent; after that, the printing and post-processing stages can be arranged. In this case, we used TPM3D P360 to print the orthosis, and the general PA12 material Precimid1172Pro is selected. The material features with good mechanical property and durability, wear-resistant, fatigue-resistant and durable while exerting enough orthopedic force on a patient, and can be worn by the patient for a long time.

If larger size or multiple braces need to be printed at one time, the TPM3D S480 and P550DL systems can be used to print.

When the orthosis is printed, we process it with Chemical Vapor Smoothing to make it more smooth, tough, waterproof and dirt-resistant, effectively avoiding the growth of bacteria. Finally, it can be worn after installing the lining and tie. The whole process takes about 2 days.

Through the patient's X-ray, it can be seen that the patient's thoracic spine has been improved to 9 degrees, lumbar spine has been improved to 11 degrees, the correction rate of lateral curvature has exceeded 50%, vertebral body rotation, pelvic deviation and other phenomena have been improved, and the overall correction effect is ideal.

C and S forms of scoliosis

The treatment of scoliosis includes surgical treatment and non-surgical treatment, which should depend on the degree of spinal deformity, age, trunk balance and other factors. In general, the patient whose scoliosis angles between 20 and 40 degrees or adolescents whose scoliosis progress more than 5 degrees per year need the conservative treatment. At present, brace therapy is the most common use in conservative treatment.

Manufacturing process of traditional scoliosis orthosis:

The traditional orthosis is generally made by gypsum molding, repairing, thermoplastic plate attachment, cutting, polishing and installation of lining ties, with the advantages of relatively low price and capability of re-heat and trim. The disadvantage is that the whole process is relatively cumbersome, the gypsum molding needs the participation of patients, which reduces the experience of patients, and the production efficiency is low - an orthotist can make braces for 3-5 patients a day at most. In addition, traditional orthoses are large in size and difficult to hide, which has a great impact on the normal study and life of adolescents.

Manufacturing process of traditional scoliosis orthosis

The process of making scoliosis orthosis by 3D scanning and 3D printing technology:

In 2021, the 3D Printing Digital Medical Center was set up in Zhongshan Chenxinghai Hospital, relying on TPM3D's laser sintering 3D printing technology, it manufactures customized health care and rehabilitation products to provide precise medical solutions for patients.

Let's take a practical case of Chenxinghai Hospital to understand how we use 3D printing technology to make scoliosis orthosis:

Patient's condition: a 13-year-old girl, thoracic scoliosis 15 °, lumbar scoliosis 23 °, the degree of scoliosis increased year by year.

Treatment: Wear nylon 3D printed scoliosis orthosis.

The process: Firstly, performing 3D scanning on a patient to get her data; Then, designing and modifying the model based on the required data, so as to ensure the comfort of the patient when wearing and achieve the effect of orthopedics to the maximum extent; after that, the printing and post-processing stages can be arranged. In this case, we used TPM3D P360 to print the orthosis, and the general PA12 material Precimid1172Pro is selected. The material features with good mechanical property and durability, wear-resistant, fatigue-resistant and durable while exerting enough orthopedic force on a patient, and can be worn by the patient for a long time.

If larger size or multiple braces need to be printed at one time, the TPM3D S480 and P550DL systems can be used to print.

When the orthosis is printed, we process it with Chemical Vapor Smoothing to make it more smooth, tough, waterproof and dirt-resistant, effectively avoiding the growth of bacteria. Finally, it can be worn after installing the lining and tie. The whole process takes about 2 days.

Manufacturing process of 3D printing scoliosis orthosis

Through the patient's X-ray, it can be seen that the patient's thoracic spine has been improved to 9 degrees, lumbar spine has been improved to 11 degrees, the correction rate of lateral curvature has exceeded 50%, vertebral body rotation, pelvic deviation and other phenomena have been improved, and the overall correction effect is ideal.

Radiographs of patients before and after wearing orthosis