With the increasing awareness of environmental protection and energy conservation, lightweighting has become a hot topic in the automotive industry. As a promising emerging technology, nylon 3D printing, also named as SLS 3D printing , is gradually revolutionizing the automotive manufacturing industry. Today, we will reveal the application value and potential of SLS 3D printing technology in the automotive field.

Before starting, let's take a look at the advantages of nylon materials. This engineering plastic has ultra-high strength, stiffness and wear resistance while also having good corrosion resistance and processing performance. These characteristics make nylon material popular for manufacturing auto parts.

So how exactly can SLS 3D printing be applied to auto parts?

Firstly, it can help achieve lightweight design which reduces weight and improves fuel efficiency! Compared to traditional metal materials, nylon is lighter yet stronger. Therefore, using SLS nylon 3D printing technology to produce parts enables lightweight design while allowing customization according to different needs. For example, Ford successfully manufactured an intake manifold using this technique for use on their race cars during the 2015 Daytona 24-hour endurance race - not only was it lightweight but had super high strength that greatly improved fuel efficiency.

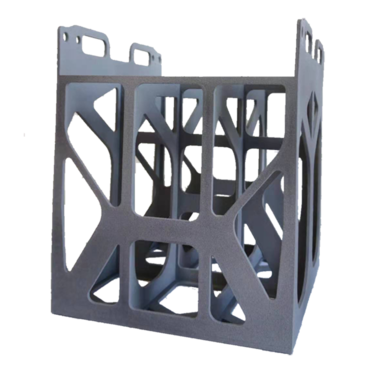

Secondly, nylon material has excellent wear resistance which makes it ideal for making frictional components such as gears or bearings. These components need to have high wear resistance and durability ensuring long-term stable operation, A luxury car brand like Porsche used this technique to manufacture seats with complex lattice structures. They were specially treated so that they had higher surface smoothness, and more flexibility in terms of colour. In use, it not only resists wear but also enhances comfort levelsand aesthetic appeal too!

In addition, the corrosion-resistant properties make Nylon very suitable for making chemical storage tanks, pipelines etc. The zero-emissions 'Ford GT Supercar' benefited from using these property features when its doors were made from this material, as was its engine hood and other parts. Through special treatment, the nylon 3D printing technology allowed it to have better corrosion resistance performance. Whether on city streets or racetracks, it guarantees absolute safety and stability.

Finally, Nylon is easy to process into shapes and can be rapidly customized through SLS 3D printing technology. Compared to traditional casting and machining processes, the use of 3D printing technology directly converts design files into physical models which can then be modified according to actual needs. This not only greatly shortens the production cycle but also improves production efficiency while meeting personalized consumer demands.

In summary, SLS nylon 3D printing technology has wide prospects and value in the automotive application field. It can be applied to various types of auto parts such as engine components, transmission systems, chassis, and bodywork. Moreover, this technique helps automakers achieve faster product development and customized production thereby increasing productivity while reducing costs. With continued technological advancement and improvement, it is believed that SLS nylon 3D printing technology will have even wider applications in the future.

TPM3D is a well-known Chinese brand specialized in SLS 3D printing technology and 3D printing service for many years. We have many successful cases in the fields of automotive, and have close cooperation with globally renowned automobile manufacturers, helping them to quickly develop new products and achieve cost reduction and efficiency improvement goals. For more information, please visit our website at english.tpm3d.com or contact us at tpm3d.printer@gmail.com.