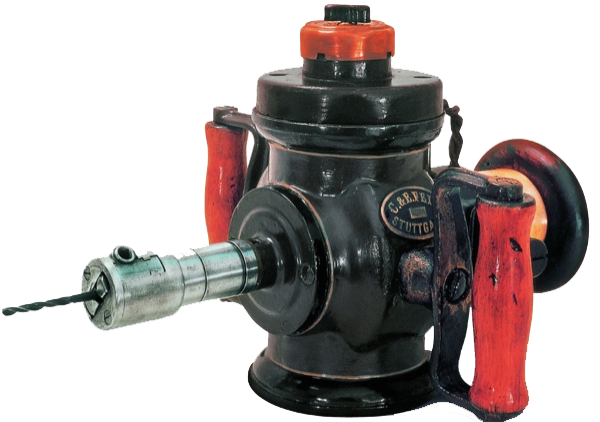

Efficiency improvement has always been one of the driving forces for innovation and progress. Since Germany-based FEIN made the world's first DC hand-held electric drill in 1895, cases have been made with aluminum alloy and thermoplastics in order to make electric drills lighter and more efficient.

The world's first DC hand drill

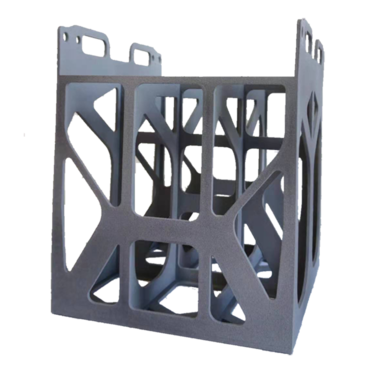

Nowadays, users have put forward higher requirements: electric tools should not only be efficient, light, fashionable and nice-looking, but also be safe at the same time. In order to shorten the R&D cycle, bring forth new ideas and seize market opportunities, manufacturers have shifted their attention to a new technology: SLS 3D printing technology. Compared with traditional CNC machining, SLS 3D printing, being insensitive to the complexity of the models, requires no complicated programming procedures. With the availability of a three-dimensional model, it can be printed and integrally molded. In addition, compared with the injection molding process, SLS technology can achieve high precision while saving the high cost of die sinking in the early stage of the project. The printed cases, similar to injection molded parts, also have good mechanical strength and durability and can be tested directly after the installation of other components. Finally, compared with other 3D printing technologies such as FDM and SLA, SLS technology has higher printing efficiency and lower cost for stackable parts, and can directly form various composite polymer materials, such as composite nylon materials with glass beads or aluminum powder, which is especially suitable for rapid batch production of power tool prototypes.

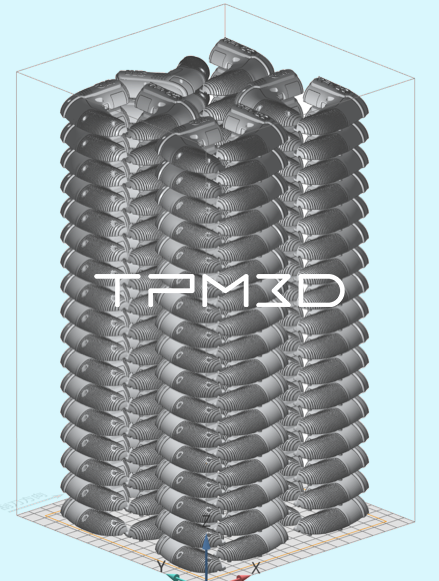

Rapid mass production through stacking

TPM3D, as a professional manufacturer of industrial SLS 3D printing equipment, is also establishing more presence in the market of electric tools. TTI & CROWN, which are world-renowned electric tools suppliers in home decoration and construction area, all using TMP3D’s SLS 3D printing equipment for product R&D. Meanwhile, TPM3D is constantly developing materials and exploring applications: Precimid1172Pro GF30 BLK, a gray-black glass reinforced nylon material, is being widely used. Featuring high heat resistance, bending strength and impact strength, it is very suitable for the actual working conditions of electric tools such as vibration, heat and friction. In addition, with excellent printing accuracy and durability, this material can be made into parts that can be used for a long time.

TPM 3D’s mass production capacity of electric tools

Another widely used material is aluminum powder reinforced nylon material (Precimid1171Pro AF40), which is a composite material composed of white nylon 12 powder mixed with 40% gray aluminum powder. This material not only has good heat and impact resistance, but also has high hardness and good machinability. In addition, the model has metallic-textured surface, which can well simulate the appearance of electric tools.

When applied in the R&D and design of electric tools, TPM3D SLS 3D printing technology provides designers with more test samples at lower cost in a shorter cycle for functional verification and accuracy testing, helping designers detect product defects and deficiencies at the earliest time possible, and quickly complete the iterative process of modification, manufacturing and retesting within 48 hours, which greatly shortens the R&D cycle of new products, reduces the processing cost, improves the R&D capability of the company and realizes cost reduction and efficiency improvement.