SLS printer | P550DL is equiped with two independent high po

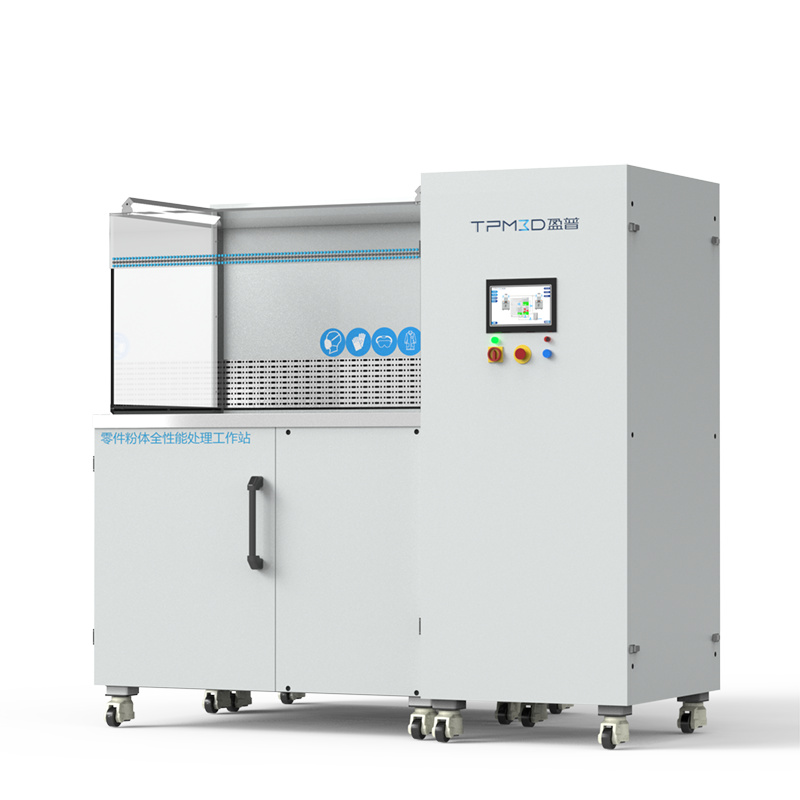

PPS - Parts & Powder Processing Station

All steps, such as laser sintering powder additive manufacturing, component unpacking, powder filtration, mixing, conveying and dust collection,are finished in different kinds of equipment. The transfer of powder among different kinds of equipment possibly causes leakage and needs a lot of energy and time of operators. Although operators can operate the equipment and treat the powder skillfully, the treatment of powder in SLS additive manufacturing needs both skill and physical strength. The Parts & Powder Processing Station (PPS) researched and developed by TPM3D team for 3 years completely eliminates the impact of powder leakage on the environment and makes the part cleaning and powder treatment easy. Users can save time and efficiently finish mass production tasks. The combination of PPS and TPM3D S serials laser sintering system can realize the clean production mode and can retain the traditional manual powder feeding mode. The printing materials can be easily replaced if necessary.

- Prodcut Detail

Function Description:

Technical Data(360 model)

- TPM3D released an innovative clean production solution, the Part & Powder Processing Station (PPS), which provides a perfect solution to prevent powder leakage. The PPS solution not only keeps your work place from any dust pollution, but also helps save your production time and cost. Both automatic and manual operation modes are available on the PPS,which provides you with more flexibilities when using the TPM3D SLS AM system

Technical Data(360 model)

- Size:2285×1560×2070mm

- Weight:500kg

- Powder feeding rate:50kg/h

- Maximum power:4kW

- Air pressure requirement:≥0.5MPa

- Air volume requirement :≥200L/min

- Dust explosion-proof level(GB3836/GB12476):Dust explosion-proof zone 22

- Noise:≤70db

- Power:380V,3/N/PE,10A,Avg 2kW

- Maximum capacity:1 PPS for 2 SLS systems

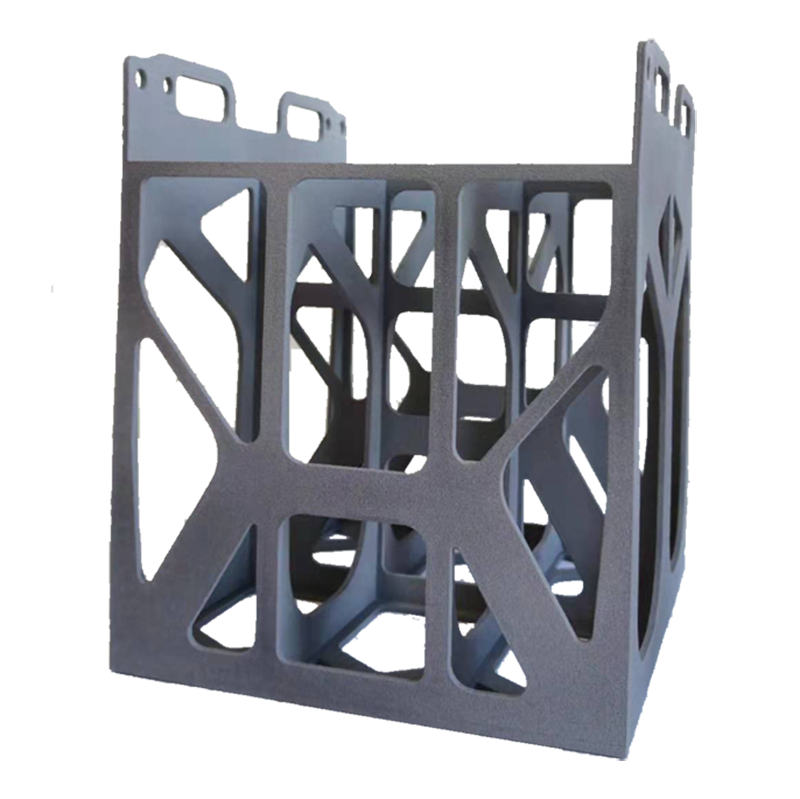

Used for Selective Laser Sintering production systems.