PEEK model printed by SLS(left) and printed by FDM(right)

The Mechanical and Energy Engineering Department here has acquired the TPM3D S320HT High Temperature Laser Sintering Additive Manufacturing System through cooperation with Shenzhen Key Laboratory for High-performance Additive Manufacturing of Advanced Materials. Also we have developed our own PEEK polymer material and molding techniques. Our main research application includes medical implants, biocultivation, high-end manufacturing. We have achieved stable and controllable printing processes that can produce high performance component with great industrial application prospects.

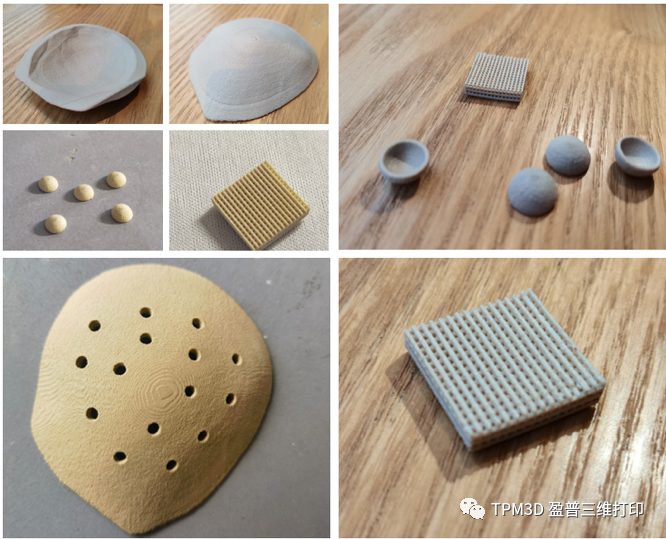

Various models printed by TPM3D S320HT

This is a certified TPM3D 320HT laser sintering additive manufacturing system by Germany’s TÜV Rheinland with multiple customers already using it successfully. It can maturely print PEEK and PEKK materials, and has the following functions:

1. Ultra-high temperature LS printing: The powder bed and forming cylinder reach 350 ℃ / 300 ℃ respectively to allow for the printing of high temperature materials such as PEEK / PEKK.

2. Flexible printing size: S320HT is small to medium-sized molding equipment with internal size of 320×320×380mm. Besides material and process development, it could also be used for new product development and small-scale production for high performance material.

3. Flexible powder replacement: It has an open breakout station (OBS), thus making cleaning, filtering, powder replacing faster which is more suitable for material & process development.

4. Oxygen concentration monitoring: The oxygen concentration monitoring system displays real-time oxygen content in the device.

5. Built-in nitrogen generator: No external nitrogen tanks or nitrogen generators required to avoid unnecessary troubles and expenses.

6. Adjustable temperature in designated height areas: This feature allows for freedom in placement and utilization of molding space without any restriction regarding temperature levels within specific heights.

7. Parts can be easily added to the printer during printing and also removed; powder cylinder can be separated from the high-temperature chamber for addition of parts and powder during the printing process. This means that if there is a rush to complete printing, it is possible to add directly to the system already in operation rather than waiting for the next start-up.

8. Optimized powder spreading device: The smart dual scraper does not require manual leveling; it has more compatibility with different materials. It could print such materials as nylon 12, nylon 11, nylon 6, TPU, PP GF, glass fiber filled nylon, carbon fiber filled nylon, aluminum powder filled nylon, PEEK/PEKK etc.

9. High material reusability: A blend of 20% fresh powder with recycled power will produce excellent performance (PA12).