At the beginning of 2025, Antarctic Bear, a mainstream media in China’s 3DP industry, organized a special feature titled:”2025 outlook by 3DP company CEOs”, inviting Ms. Lucy Zhai, the CEO of TPM3D, a laser sintering 3DP manufacturer, to share her insights on TPM3D’S product, technology and market prospects in 2025.

Ms. Lucy Zhai, CEO of TPM3D

2024 Year in Review

In 2024, TPM3D achieved substantial performance growth, with overseas business showing

particularly notable progress. The brand’s visibility has greatly increased, attracting

attention from mainstream international media and gaining substantial recognition at major

trade shows such as Formnext and TCT Asia. TPM3D has expanded its team size and further

strengthened its R&D , production and after-sales service systems, laying a solid

foundation for long term development.

TPM3D team

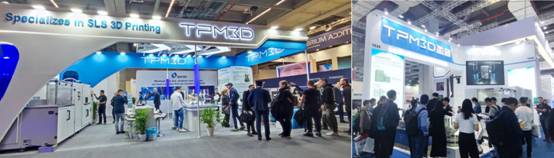

TPM3D shined

in Formenxt and TCT Asia

Envisioning the Year 20025

In 2025,TPM3D will focus on the innovation and application expansion of SLS3D printing

technology, deepen the research and development of equipment and materials, expand

production capacity and ensure supply to meet the diverse needs of the market.

1. Equipment R&D and Market Expansion

With the advancement of powder bed 3D printing technology, products from new entrants such

as HP and Formlabs have gained popularity in the market, reflecting an increased acceptance

of SLS (Selective Laser Sintering) powder bed fusion technology among users.TPM3D will

continue to deepen its efforts in SLS 3D printing technology. In terms of depth, the company

will develop large-scale equipment with four lasers to handle larger parts and improve

production efficiency, meeting the demands of large-scale industrial applications.

Simultaneously, the company will penetrate the consumer-grade market, planning to launch

Desk-top SLS 3D printing devices suitable for small and medium-sized enterprises by 2025.

These devices will offer better cost-performance ratios and user-friendliness, further

expanding market coverage.

2. Innovative Materials, Expanded Applications

TPM3D will focus on development high-performance materials and innovative processes to meet

diverse needs from the market.

For the rapidly growing drone market, the company will introduce carbon fiber-reinforced

nylon material to support lightweight design and enhance drone performance. This material

combines high strength with low weight, ideal for applications requiring lightweight

solutions. Additionally, TPM3D will develop a high-toughness nylon material for

rehabilitation support products, improving durability and comfort. It will be suitable for

hand orthoses, ankle braces, scoliosis orthoses, and spinal surgical braces.

High-toughness

nylon material for printing scoliosis orthoses.

With technological advancements, an increasing number of users aim to directly produce end-use products using SLS 3D printing technology. TPM3D will integrate additive and subtractive manufacturing techniques, develop new materials and processes, and reduce the cost of final products. This initiative has the potential to revolutionize the additive manufacturing market, with plans for mass production by 2025.

3. Global Expansion and Capacity Upgrade

Powder bed 3D printing technology demonstrates higher maturity and application potential in

overseas markets. To align with global standards and promote the globalization of TPM3D's

products and services, we will continue to enhance our overseas market presence, strengthen

brand promotion, and expand market outreach, thereby increasing TPM3D's global recognition

and influence.

TPM3D's New

Factory in Anhui Province

“I am optimistic about the development prospects of the powder bed technology market. From

the trends at Germany's Formnext and the Rapid+TCT exhibitions indicate that the global

expansion of Chinese enterprises is both a choice and an inevitable trend of the times.

TPM3D will seize this opportunity to accelerate its strategic deployment and business

expansion in overseas markets.

Chinese companies possess unique advantages, such as robust R&D capabilities, a

well-established supply chain, and extensive manufacturing expertise. However, given the

current global political and economic environment, we will adopt a prudent strategy,

strengthen weak areas, enhance the support system and service network for overseas partners,

and elevate brand recognition and reputation to ensure sustainable development in the global

market.”